Blog

Blog

Branch dejections. Fertilitzant or residue?

17th November 2020 - News

Slurry used as fertilizer is an excellent manure when applied correctly, but it can become an environmental issue in areas with a high concentration of livestock when the balance between agricultural activity and livestock production is disrupted. Under these conditions, crop over-fertilization usually occurs. Plants are unable to absorb all the nutrients, and the slurry becomes a pollutant for the soil and the atmosphere, but especially for surface and groundwater.

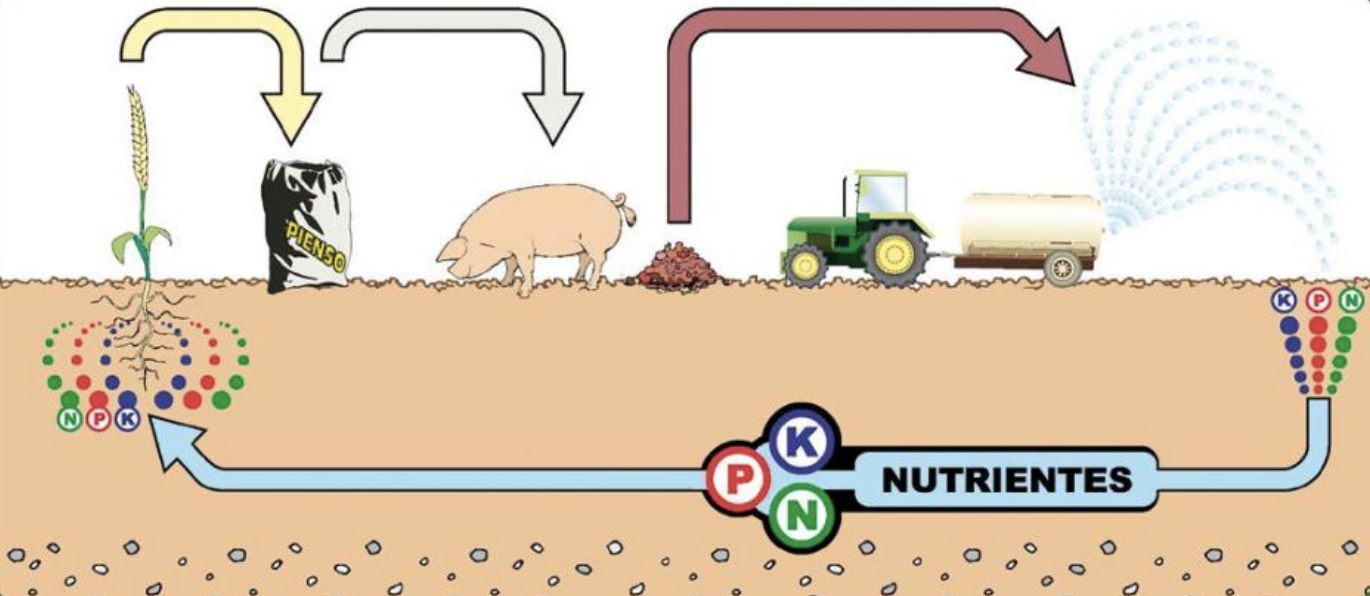

Applying slurry to agricultural soil returns nutrients previously extracted by crops. It is the nutrient life cycle: plants absorb them, animals ingest them in the form of feed, and they are returned to the soil as slurry or manure.

However, if the applied dose is excessive, it leads to production losses, unnecessary expenses, and environmental damage. These impacts can be of two types: first, as the nitrogen in slurry is in ammoniacal form, it volatilizes and emits into the atmosphere; second, ammoniacal nitrogen in the soil transforms into nitrate form. This form is soluble and can be absorbed by crops but is also prone to leaching into deep layers, contaminating aquifers or watercourses.

NITRATE DIRECTIVE

Alarmed by water pollution, the European Union created the Nitrate Directive in 1991—one of its first legislative texts concerning groundwater contamination due to excess nitrates. The directive aims to protect water quality throughout Europe by preventing nitrates from agricultural sources from polluting surface and groundwater and promoting good agricultural practices.

The directive addresses a vital need: ensuring pure and clean water to preserve the health and well-being of humans and natural ecosystems. Although nitrogen is an essential nutrient that supports plant growth, in high concentrations, it becomes harmful to people and nature. Agricultural use of nitrates in fertilizers and chemicals is a major source of water pollution. Agriculture is responsible for more than 50% of total nitrogen discharges into surface waters.

To prevent and correct this issue, EU countries proposed the following actions:

- Designate vulnerable zones.

- Develop mandatory action programs for these zones.

- Monitor the effectiveness of action programs.

- Analyze nitrate concentrations in groundwater and surface waters.

- Implement an extensive monitoring program and submit a comprehensive report every four years on the directive's implementation.

- Develop a code of good agricultural practices that farmers may voluntarily follow.

- Provide training and information to farmers.

- The European Commission will present a report every four years based on national information received.

Additionally, the directive limits the amount of manure applied per hectare to that which contains 170 kg of nitrogen (N) in areas where drinking water contains more than 50 mg/l of nitrates (vulnerable zones). Member states may permit manure applications containing up to 210 kg N per hectare in non-vulnerable zones, i.e., where nitrate levels are below 50 mg/l.

The report covering the period 2004–2007 stated that nitrate concentrations in surface waters remained stable or decreased in 70% of monitored zones. Water quality remained stable or improved in 66% of groundwater monitoring points.

All EU Member States have developed action programs: there are more than 300 programs across the EU, and their quality continues to improve. In the 27 EU Member States, 39.6% of the territory is subject to action program implementation. Farmers are increasingly proactive regarding environmental protection and are exploring new techniques, such as manure processing. Agriculture continues to be the main source of water-related problems, and farmers must adopt more sustainable practices. Massive efforts are needed to ensure high-quality water throughout the EU.

The report for 2008–2011 highlights that livestock farming is one of the main agricultural pressures on the environment. High local or regional concentrations pose a significant environmental risk, as manure production is not balanced with land availability and crop needs. This imbalance leads to nutrient surpluses, much of which is eventually lost to water (nitrates and phosphates) and air (ammonia and nitrogen oxides) unless exported outside the region.

The number of groundwater monitoring stations in the EU-27 increased by about 10% compared to the 2004–2007 period, reaching 33,493 stations. In 2008–2011, 14.4% of groundwater stations exceeded 50 mg of nitrates per liter, and 5.9% were between 40 and 50 mg/l. This reflects a slight improvement compared to the previous period, where 15% exceeded 50 mg/l and 6% were between 40 and 50 mg/l.

The 2012–2015 report affirms that, despite some progress in reducing the use of mineral fertilizers, there are still many gaps in basic measures taken by states to address agricultural pressures. Control measures for phosphate and nitrate emissions outside vulnerable zones designated under the Nitrate Directive are often lacking.

The reports show that campaigns have been conducted to inform and train farmers on proper fertilizer use, but continued efforts are necessary. It is also noted that many Member States still need to improve in several areas, such as identifying and controlling pollution hotspots and developing stronger action programs.

A positive trend noted in the report is the growing interest among livestock farmers in innovative feeding methods and new manure processing techniques, often combined with energy generation. Community farmer groups, mainly from Belgium, Spain, and the Netherlands, have invested in corporate projects in this area.

HOW TO REDUCE NITROGEN?

Given the issue of slurry surplus in areas with high livestock density, and the increasingly restrictive legislation, it is essential to properly manage livestock waste and plan strategies to minimize its production. Several action levels exist to reduce nitrogen concentration:

Source Reduction: Through feed and water management on farms.

- Feed: Order AAM/312/2014, “Application of reduction levels for nitrogen excretion in pig farming,” establishes criteria for reducing nitrogen excretion via improved feeding. Three types of measures can be adopted to reduce nitrogen in excreta: increasing the digestibility of feed protein, improving the balance of amino acids in the diet, and avoiding protein excess relative to the animal’s needs.

- Water: Improvements can be made by managing drinkers, efficiently cleaning interior materials, or managing rainwater collection. These actions are critical for reducing the volumetric production of slurry.

Emission Reduction: Storage and Application

- Storage: Slurry storage systems must ensure total watertightness to prevent leaks, fractures, or infiltration. Storage capacity must be adequate to hold slurry during periods when field application is not possible (4–6 months).

- Application: Always apply slurry in measured amounts according to crop needs and spread it evenly. When using traditional spreading equipment or multi-nozzle arms, perform shallow tillage as soon as possible to bury the slurry and prevent atmospheric emissions. Without a doubt, injection systems (disk, tine, or grass injectors) with trailing hose booms are the most effective.

Manure Processing

If there is a surplus of slurry that cannot be applied to agricultural land, treatment systems can be implemented to partially or fully treat the excess slurry.

- On-farm application of simple pre-treatment systems with low investment to improve the slurry’s agronomic properties and reduce environmental impact. Solid-liquid separators are the best tools to achieve these goals.

- Large-scale treatment systems that purify slurry. These require high investments and are suitable for areas with large slurry surpluses. Previous measures can complement correct manure management.

TECNAPUR

Since its beginnings, Rotecna has aimed to provide the best solutions to the ever-evolving and entrepreneurial pig farming sector. Today, challenges include improving animal health, welfare, and environmental sustainability. Tecnapur offers sustainable solutions to the complex issue of livestock waste.

The TP-01 solid separator by Tecnapur offers a cost-effective and efficient solution for optimizing livestock waste. Solid-liquid separation is the first step to reducing nitrogen and phosphorus in farm slurry or for subsequent treatment systems. It can reduce slurry volume by up to 15%, yielding 150 liters of solid material (with 20–25% dryness) and 850 liters of effluent per 1,000 liters of raw slurry. The solid portion can be composted, used to produce biogas or electricity, sold as fertilizer, burned as fuel, and transported over long distances at low cost.

Tecnapur solids separator. Photo: Rotecna.

The solid phase is odorless and may contain up to:

- 25% total Kjeldahl nitrogen (TKN),

- 50% total phosphorus (TP),

- 20% potassium (K),

- 30–50% of the original total solids.

The liquid phase requires smaller storage ponds and does not form surface crusts, as it remains more homogeneous. It can be treated using physicochemical or biological systems before discharge into rivers or applied directly or diluted with irrigation water in fields. It is easier to pump and apply, does not form crusts during field application, and infiltrates the soil much more easily, preventing runoff and requiring less land area for the proportional amount of nitrogen.

A serious issue being observed is that when fertilizing fields, slurry is not chemically balanced, and plants cannot absorb all the phosphorus, which accumulates in soils—even though phosphorus is a scarce mineral. Because the initial process separates a significant amount of phosphorus into the solid phase, using the resulting liquid as fertilizer is no longer a problem, and over-application of phosphorus in soils is avoided.

With the TP-01 solid separator, Rotecna provides an innovative tool to improve the fertilizing properties of slurry, reduce its environmental impact, and address the issue of nitrogen surpluses (which limit livestock expansion) in high-density livestock regions. Rotecna’s R&D Department, through the Tecnapur product line, continues to research innovative solutions for managing livestock waste.