Blog

Blog

How can we minimize fattening costs?

05 of February of 24 - News

The fattening phase, and specifically the consumption of feed during this period, represents the highest production cost for pig companies. Good management of feeding and handling is key to minimizing this impact. Some of the keys to doing so were presented by professionals from the pig sector in a new edition of the UAB and AVPC Porcine Conferences, held from 31st January to 2nd February.

Image from the UAB and AVPC Porcine Conference. Photo: Rotecna.

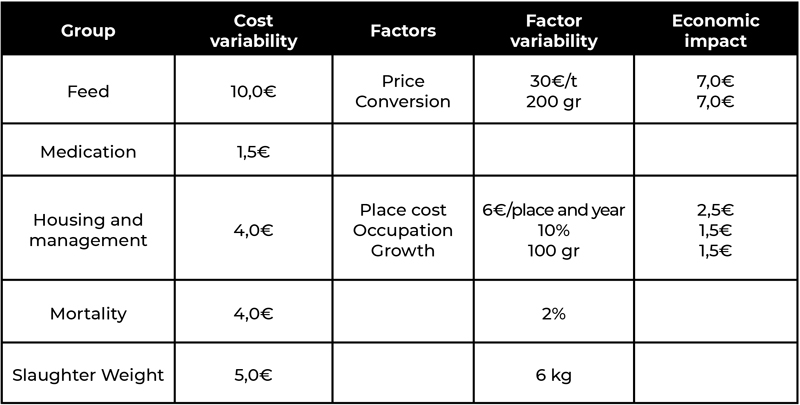

It is estimated that fattening accounts for 67% of the final production cost. According to data from SIP Consultors referring to the year 2023, the cost of this phase amounted to around 114€ per pig with a variability that can reach 14€ between low- and high-cost companies. According to Joan Rocadembosch, from SIP Consultors, we can minimize these costs by analyzing obvious factors such as feed, medication or growth, but it is also important to pay attention to less common issues such as an analysis of occupation, economic growth and slaughter weight. The economic impact of these factors is significant and beneficial to increase the profitability of the fattening process.

Source: SIP Consultors.

On the other hand, the correct management of fasting prior to sending the animals to the slaughterhouse also allows performance to be optimized, something that will later be reflected in the results. This was explained by Rafael Guillén, from Grupo Jorge, who highlighted that prolonged fasting, especially over 30 hours, together with poor management of the animals, carries the risk of weight loss in the carcasses. In this sense, the rate of weight loss of the carcass practically triples after 24 hours of fasting, significantly decreasing the yield of the carcass. To avoid this effect, effective fasting of 12 to 14 hours before loading is recommended, which plus the loading, unloading and transportation time, and the waiting time in the slaughterhouse pens add up to a total fast of 22 to 26 hours.

Feeding strategies are another important point when it comes to improving production efficiency in fattening. Improving the conversion rate (CI) during this period is key to farm profitability, but this is often confused with low production cost. Pau Aymerich, Vall Companys technician, pointed out that the relationship between both concepts depends on changes in the nutritional profile, in the facilities, management or mortality. In this sense, when designing nutritional programs, it must be taken into account that adjusting the nutritional concentration in the diets will affect both the cost of the feed and the IC. Finding a proper balance between these parameters is crucial to determining production cost and profitability. In line with the design of nutritional programs, it also proposes deciding whether to feed the entire population in the same way or segregate it according to weight or sex to feed more closely to individual requirements. Such segregation offers opportunities for improvement in terms of costs and CI, although with significant logistical challenges. The application of these concepts can lead to significant improvements in profitability during fattening, allowing feeding that is more tailored to the individual requirements of the pigs.