Blog

Blog

Keys to good cleaning and disinfection in pig farms

13th November 2025 - News

Cleaning and disinfection of pig farms are an essential part of any farm’s biosecurity plan. A well-designed protocol not only reduces pathogen pressure but also improves production performance, decreases antibiotic use, and extends the lifespan of facilities through proper hygienic management.

Why cleaning and disinfection impact health, performance, and costs?

Thorough cleaning and disinfection are fundamental to ensuring the efficiency and sustainability of pig production. When properly applied, they help reduce mortality, improve average daily gain, and optimize the feed conversion ratio. In addition, they lower the use of medicines and antibiotics, thereby enhancing animal health and farm profitability. A good cleaning and desinfection program also ensures compliance with sanitary regulations, reduces pathogen load, and prevents disease recurrence. Altogether, this translates into better animal welfare, stronger production parameters, and more reliable traceability.

Conversely, poor hygiene can lead to disease outbreaks, significant economic losses, and a deterioration of animal welfare.

How does cleaning fit into the biosecurity plan?

Cleaning should not be viewed as an isolated task but rather as a cornerstone of the overall biosecurity plan. Its effectiveness depends on proper planning and coordination with other preventive measures. Firstly, the separation of clean and dirty zones helps define areas with different risk levels and control entry and exit flows, preventing cross-contamination. Likewise, access and movement control—of people, vehicles, and animals—should follow a one-way flow to minimize contact between contaminated and clean areas.

Another key element is the sanitary downtime, the period after a barn is emptied that includes cleaning, disinfection, drying, and verification before re-stocking. Its duration should be adjusted based on organic load, ventilation, and seasonal conditions.

Finally, it is essential to consider the concept of biofilm, microscopic layers of microorganisms and organic matter adhering to surfaces such as water lines. These structures are highly resistant and can reduce the effectiveness of disinfectants if not removed beforehand using detergents and mechanical action.

Cleanliness is a pillar within the biosecurity of a farm.

Step-by-step cleaning and disinfection protocol for pig farms?

A correct procedure must follow a logical and orderly sequence. The following protocol outlines the steps required to ensure effective cleaning and disinfection, guaranteeing compliance with biosecurity standards and maintaining optimal sanitary conditions on the farm.

0) Preparation

Before starting, remove all animals and movable equipment from the facility. Personnel must always wear appropriate personal protective equipment (PPE) to ensure safety. Disconnect electrical power if necessary and protect panels, sensors, and other electronic components from damage during the cleaning process.

1) Dry Cleaning

The first step involves removing all manure, used bedding, feed residues, and accumulated dust. This can be done by sweeping or controlled blowing to reduce organic matter and improve the efficiency of the detergent applied in the next phase.

2) Soaking and Detergent Application

Next, thoroughly soak all surfaces—floors, walls, ceilings, feeders, drinkers, and corners—with water, then apply an appropriate detergent (alkaline, enzymatic, or foaming, depending on the type of dirt). Allow the product to act for at least 30 minutes to soften organic material and facilitate its removal.

3) Pressure Rinsing

After the detergent’s contact time, rinse with high-pressure water using power washers or lances. The recommended sequence is from top to bottom: ceilings first, then walls, floors, drains, drinkers, and feeders, ensuring a thorough and uniform cleaning.

4) Disinfection

Once surfaces are clean, apply a suitable disinfectant—such as quaternary ammonium compounds, glutaraldehyde, hydrogen peroxide, or peracetic acid—respecting the recommended dosage and a minimum contact time of 30 minutes. To maintain program effectiveness, periodically rotate active ingredients to prevent bacterial resistance.

5) Drying and Ventilation

All surfaces must be completely dry before animals are reintroduced, as moisture reduces the effectiveness of disinfectants and promotes microbial growth. Good ventilation accelerates drying and ensures a safer environment.

6) Reassembly and Testing

After drying, reinstall previously cleaned feeders, drinkers, and silos. If necessary, apply an antifungal treatment inside silos to prevent mold growth. It is also important to verify the proper functioning of water and feeding systems before the barn is put back into operation.

7) Final Validation

The process concludes with an assessment of cleaning and disinfection effectiveness using ATP tests or bacteriological swabs. Finally, a checklist signed by the biosecurity manager certifies that the facility meets the required standards before reopening.

Area and equipment specific cleaning

Each area of the farm has particular characteristics that require specific attention within the cleaning and disinfection program.

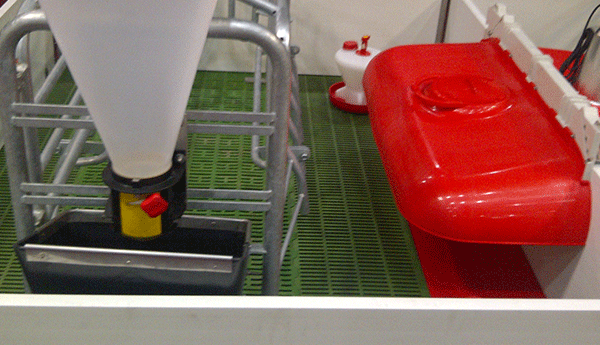

In farrowing rooms, the presence of newborns and the high organic load demand more frequent and careful hygiene, with cleaning between batches and additional treatments during critical periods. Mild detergents and thorough rinsing are recommended, along with regular inspection of drinkers and biofilm control in nipples and water lines. Special attention should be paid to hidden areas such as floor-to-wall joints, under feeders, and corners behind movable crates.

During the fattening phase, where organic matter accumulation is greater, deep cleaning between batches is advised to reduce infection pressure. Water lines and drinkers should undergo regular flushing and internal disinfection to prevent biofilm formation.

Silos and feeders must be cleaned internally on a regular basis to prevent mold and mycotoxin development, which can affect feed quality and animal health. Finally, vehicles and loading docks must follow a strict cleaning and disinfection protocol, with an access log to ensure traceability and prevent pathogen introduction.

Hygiene in maternity requires more frequent and careful attention. Photo: Rotecna.

Cleaning and disinfection on pig farms are not routine tasks but an investment in health, animal welfare, and profitability. Implementing a clear protocol with defined responsibilities and verified results ensures a healthier, more efficient, and sustainable production environment.