Blog

Blog

Trends in farrowing equipment

18th November 2025 - News

In the farrowing phase, equipment plays an increasingly important role in achieving better results in both welfare and efficiency. The latest innovations are redefining the design and operation of farrowing units, incorporating solutions aimed at optimising sow comfort, improving piglet vitality, and facilitating daily management. From choosing the right farrowing module to implementing different housing systems, every element directly influences animal performance.

Electronic feeding as a strategic pillar

One of the most significant transformations lies in the adoption of feeding management equipment in farrowing, essential in any modern farm. Electronic feeding systems, such as Rotecna Dositronic M, make it possible to schedule multiple daily meals, adapt intake curves for each sow, and monitor consumption remotely. This increases feed intake during lactation, reduces labour needs, and provides individual records that support decision-making. Such precision helps optimise milk production, improve piglet growth, and better prepare the sow for the next cycle.

Welfare oriented free farrowing design

The shift towards systems that give sows greater freedom of movement, whether through temporary confinement pens or fully open farrowing spaces, is gaining ground and emerging as a major change. In this context, choosing the right farrowing crate, including innovative options such as free access or foldable crates, becomes essential. Countries such as Switzerland, Sweden, and Norway have already advanced in this direction.

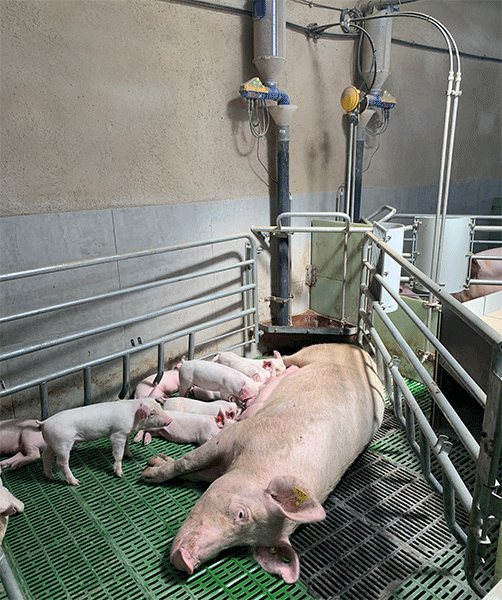

This new approach requires a complete rethinking of equipment design and calls for effective piglet-crush protection, adapted flooring, designated areas for resting and dunging, and structures that support the expression of natural maternal behaviour. For these systems to work properly, they must ensure hygiene, comfort, safety, and practical handling.

Free farrowing pen equipped with Dositronic M, Rotecna's feeding system for sows in farrowing. Photo: Rotecna.

Materials and surfaces designed to improve hygiene

The selection of materials and surfaces in the farrowing room is another key factor. PVC or polypropylene panels, compared to traditional concrete, are gaining popularity because they facilitate cleaning and disinfection, reduce water consumption, and improve overall hygiene. Plastic or cast-iron floors, heated plates, and slats designed to prevent injuries to teats or hooves all contribute to the comfort of both sow and piglet while promoting a healthier environment.

Climate control and intelligent sensors

In the farrowing environment, where temperature, humidity, and air quality directly affect sow behaviour and piglet vitality, sensing and climate-control systems have become essential. IoT sensors, CO₂/NH₃/humidity monitoring, and automated ventilation help maintain optimal conditions in the farrowing and lactation areas. This minimizes the risk of hypothermia in piglets, supports smoother farrowing, ensures optimal milk consumption, and reduces mortality.

Data, automation, and digitalisation in service of the farrowing room

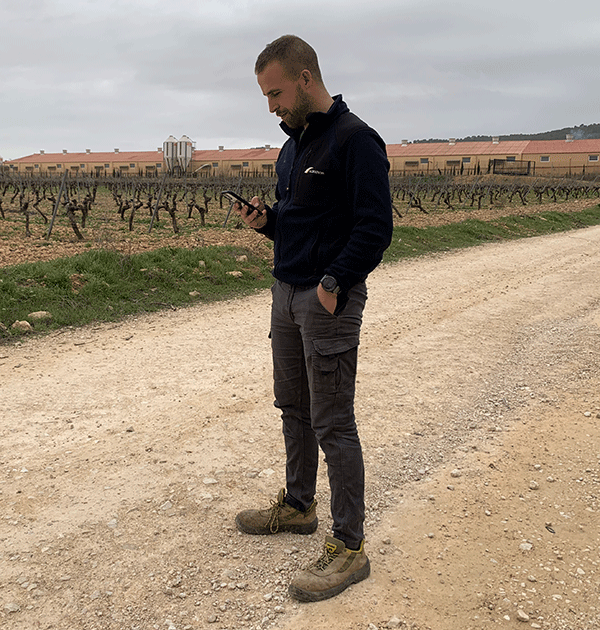

Digitalisation of the farrowing and lactation unit is no longer a trend but a necessity. Automatic feeding systems, cleaning robots, remote monitoring, and cloud-based data analysis make it possible to anticipate issues and optimise resources. As a result, the farrowing room evolves from a static space into a dynamic environment managed with precision and oriented toward maximising welfare, efficiency, and traceability.

Digitalization allows you to monitor what's happening on your farm from anywhere. Photo: Rotecna.

An integrated perspective: efficiency, welfare, and sustainability

These innovations do not merely represent isolated improvements; they define a new farrowing model focused on efficiency, animal welfare, and sustainability. Intelligent equipment, mobility-oriented layouts, hygienic materials, and advanced climate control contribute to a robust system prepared for current challenges.

This approach increases weaning weight, reduces piglet mortality, improves sow body condition at weaning, and better prepares the herd for the next reproductive cycle, while also meeting the growing expectations of consumers concerning welfare and responsibility.