Blog

Blog

Discover the advantages of working with Rotecna's Ni-2 Corners

23rd February 2021 - Success stories

With more than 40 years of experience in Italian swine production and with a farm that currently has 2,500 mothers, Carlo Alberto Gasparini, in 2013, opted for renovating its facilities and adapting them to new requirements in view of a better future. Carlo Alberto reviews with us his professional career and the evolution that his farm has undergone in recent years.

Carlo Alberto Gasparini, owner of the farm. Photo: C.A. Gasparini.

Why did you specialize in swine production?

I had just graduated in Agricultural Sciences from the University of Bologna, in 1973, when I decided to put into practice the skills acquired on the pig sector. At home we had land, and my father had a long experience in the field, but nothing related to the pig sector. This is how, with the support of my family and the help of a teacher, I built my own pig farm from scratch, an avant-garde facility for those times, with the latest technology for the sector, and all of this with 100% private investment.

How has the farm evolved over the years?

At the beginning, the farm had a capacity for 200 mothers and was closed cycle. Over the years, we have been expanding and improving the production system. Now we have more than 2,500 mothers of high genetics and, although we continue to carry out the entire productive cycle, we have bet a lot to have the different phases well separated and at a reasonable distance from each other. Thus, although the entire farm is in the lower area of the Modena plain (Emilia-Romagna region), there are three clearly differentiated areas: farrowing, weaning, and fattening. On the other hand, note that our specialization is the production of piglets with an optimal weight of 28 to 30 kilos. In this sense, we are producing an average of 60,000 piglets per year. The farm has everything necessary to guarantee the welfare of the animals, which is also a demonstrable fact if the health of the animals and the results of the farm are observed.

With this volume of production, how many people work on the farm?

We have 10 highly qualified workers in the livestock sector, who work on the farm and who take care of everything necessary to guarantee a good production in each of the phases. I oversee the company, carrying out the management, direction and coordination work, with the help and direct participation of my wife and my two grandchildren.

What feeding system is used on the farm?

For animals up to 30 kilos we use dry feed, while for sows we use liquid feed with by-products. In this sense, in the Po area, it is a consolidated custom over the centuries to use whey obtained from the manufacture of Parmigiano Reggiano cheese.

On the other hand, when it comes to equipping its facilities, you bet on Rotecna products. Why do you choose this company?

I got to know Rotecna, its work and its products, more than 15 years ago, during a guided tour that I took at its facilities in Spain. Since then, I have had the feeling that Rotecna products offer me solutions and a satisfactory answer to my needs as a farmer.

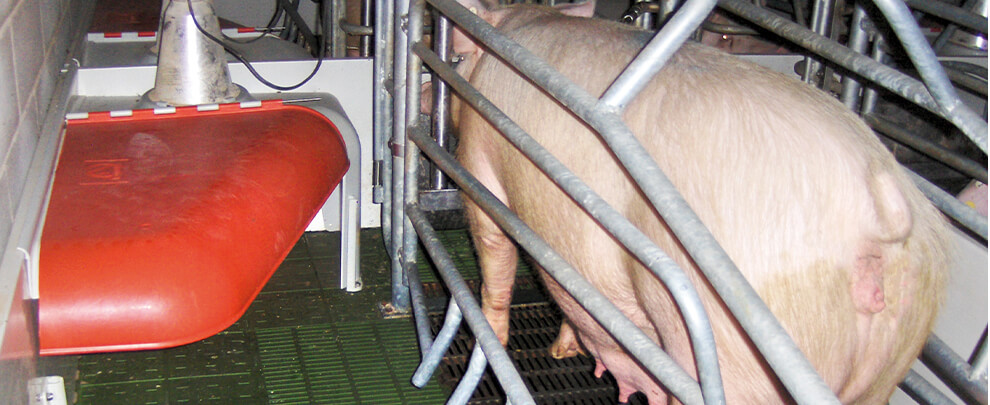

Farrowing pens with Rotecna products. Photo: C.A. Gasparini.

What are some of the Rotecna products that you have installed?

I have Ni-2 Corners, heating plates and feeders for the farrowing pens. For weaning, I have mostly feeders, specifically the TR-5.

What benefits does Ni-2 Corner bring to you?

It is a product that allows us to save thermal energy, reduce the risk of the mother crushing the piglets and increase the amount of milk produced by the sows, with the benefits that this represents in the productivity of the farm. Regarding energy savings, we have not made an exact assessment of the savings, but we can see that with the same amount of diesel with which we heated 260 pens, now, thanks to the Ni-2 Corners and good insulation of the room, we got to heat 520 places. In other words, for the same price, we now heat twice as many farrowing pens. On the other hand, the fact of being able to work with one temperature in the room and another inside the Ni-2, reduces the risk of the mother crushing the piglets, since they now take refuge inside the nest. At the same time, having a cooler temperature in the room for the sows increases their feed intake and increases their milk production, which favors the growth and development of the piglets.

Regarding your farm, what goals do you have for the future?

I believe in a better future for the sector. For this reason, I am investing to continue expanding our number of sows, which will increase the production of fattening pigs, although not proportionally. My goal is to reach 10,000 fattening pigs / year.