Blog

Blog

What benefits does electronic feeding offer us in lactation?

11th April 2023 - Studies

Gergely Horogh. Pig nutritionist.

In our work as on-farm consultants, most of the problems and the most complex challenges we face in the farrowing house are: messy litters at farrowing, many small piglets, low piglet viability, day-old diarrhea, high mortality, high farrowing mortality or even low weaning weights. Solutions to these problems often require a complex approach, but we tend to forget the importance of the most basic factor, optimal feeding. I am not referring to feeding in various phases, formulation, nutrient content (this is under the ultimate control of our feeding specialists), but what the farmer really controls is the amount of feed given, the use of optimal feeding curves and ideal feeding frequencies, this has a great impact on both the sows and piglets in the short and long term. In this article we expose a case study on a breeder farm in Hungary.

Piglet size and litter homogeneity

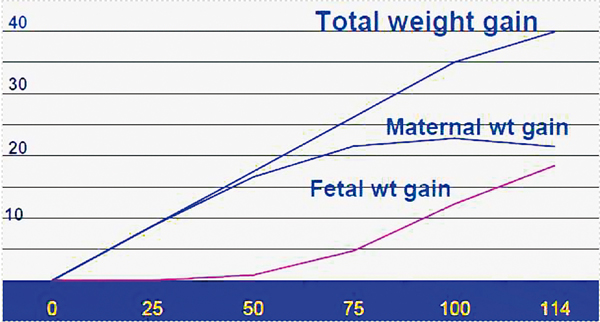

During the last phase of gestation, from about day 80 to the beginning of farrowing, the sow's nutritional needs increase significantly due to both the intense growth of the fetuses and the growth of the mammary glands and tissues preparing for colostrum and milk production. If the increased nutrient needs of the sow are not met during this period, the intense intrauterine growth of the piglets will be lost (fetal weight may even double in the last two weeks of gestation).

Weight gain in the last phase of gestation.

In addition, the sow begins to mobilize her own reserves, resulting in a loss of muscle mass and backfat before lactation begins. Therefore, we recommend that you do not reduce the sow's feed ration after the sow has been put in the farrowing pen, but maintain the increased rations from the high gestation phase (3.4-3.8 kg/day) until farrowing.

Farrowing dynamics, stillbirth of piglets

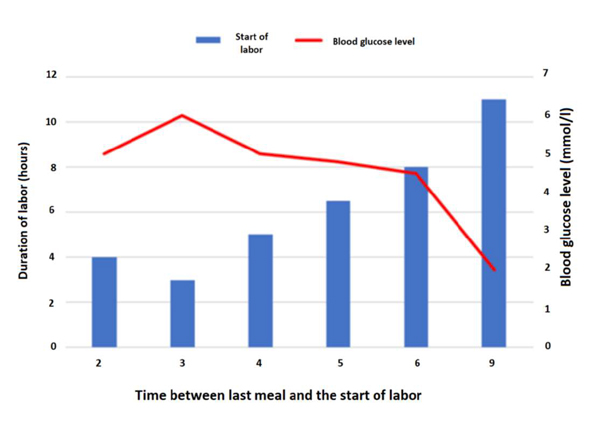

In addition to the feed ration, another important aspect is the frequency and distribution of feed, as it determines the energy status of the sow at farrowing, which affects farrowing duration and piglet viability, including stillbirth.

The starch content of the feed, which provides energy to the sow, is absorbed in the intestines in the form of glucose within 3 to 6 hours after feeding. The sow's energy supply is at its best during this period, so if farrowing is initiated at this time, a dynamic, fast and trouble-free farrowing can be expected, resulting in viable piglets.

Time elapsed between the last meal and the start of labor.

However, after this time, blood glucose levels, and thus the sow's energy status, decline. If farrowing starts 6 hours after the last feeding or later, the low energy will lead to fatigue and a prolonged farrowing. Therefore, the longer the time between the last feeding and the beginning of farrowing, the longer the duration of farrowing and the greater the risk of stillbirth. In this case, the rate of problem farrowings and assisted farrowings will increase.

So what should we do? It would be advisable to increase the number of feedings even before parturition, with 4 feedings per day at approximately 6-hour intervals.

On the other hand, what is the national (Hungarian) common practice? Before farrowing, usually 2 to 3 feedings per day are given, and of course the distribution of feedings is flexible, based more on the organization of labor than on the needs of the sow. For example, on a typical farm, the afternoon feeding is at 16:00 and the next morning feeding at 7:00. The time between the two feedings is 15 hours, far exceeding the ideal 6-hour interval.

Lactation

For lactating sows, the main objective is to ensure optimal colostrum and then that milk production is optimally initiated and maintained at a stable level.

Milk production of the sow is a key determinant of piglet viability, growth and weaning weight. However, it must also be remembered that maximum milk production must be obtained with minimum backfat and muscle loss. This is because the energy deficit in lean and fat sows has a negative effect on reproductive biology, impairing gestation and farrowing outcome. It also has a long-term effect, as poor follicle development will have a negative impact on the number of piglets and their viability in the next cycle. To avoid this, genetics companies consider a maximum of 2-3 mm of spinal column loss during lactation to be acceptable.

The amount of milk produced by a sow at the peak of lactation reaches 15-18 liters. However, this requires that a maximum feed intake of 8-10 kg is reached or even exceeded, whereas the average daily feed intake during lactation should reach 6 kg.

It is difficult to expect sows to consume this amount from 2 to 3 feedings in an 8-hour period. Obviously, it is also important to increase the number of feedings during lactation from 4 to 6 feedings covering the whole day.

Another complicating factor is the need to follow a feeding curve that perfectly meets the feeding needs of growing sows, varying the amounts required on a daily basis. Moreover, if we also take into account that the appetite and feed intake pattern of the sows varies considerably from one time of the day to another, even within the same day, we soon realize that feeding the sows according to their biological needs is far beyond the possibilities of the average farm management.

The management of one of the leading pig producers in our country saw this contradiction and decided to install the Rotecna Dositronic M automatic sow feeding system on their 4,000 sow farm. The installation of the system was completed in June 2022 in 1,026 farrowing crates. The expectation of the system was primarily to reduce manual labor while maximizing the biological needs of the previously mentioned sows.

Dositronic M is easy handling and intuitive. Photo: Rotecna.

What has changed?

The feeding schedule of the sows could be completely shifted from the previous feeding schedules, which were adapted to the physiological state. Instead of the 2 feedings previously done manually and 3 feedings from the first week of lactation onwards, 4 feedings are now done during the whole lactation period, fully automatically, reducing the need for labor to a fraction. Feeding is done in several blocks throughout the day, with the sow being able to eat the feed ration according to her own needs and appetite, in small portions, almost ad libitum.

"Supplying small amounts of feed several times a day increases feed intake and drastically reduces feed wastage".

In the pre-farrowing period, to ensure an optimal energy supply for the sows, a feeding period is included starting at 2:00 a.m., so that there are intervals of maximum 5 hours during the day without feeding.

Supplying small amounts of feed several times a day ensures a high level of feed hygiene, increases feed intake and drastically reduces feed wastage.

The program's software interface and internal units are easy to set up and operate, with color-coded information providing immediate feedback on the sows' feed intake, enabling faster and more effective detection and treatment of non-eating or sick animals. This is a great aid to farrowing management, especially in large sow herds.

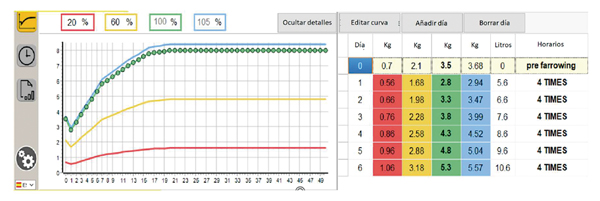

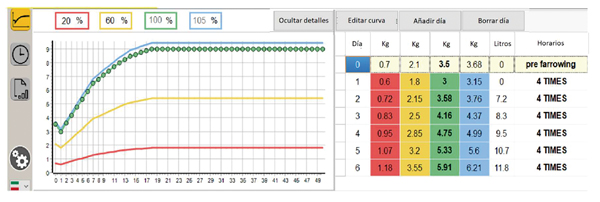

The feeding curve during lactation is adjusted to the needs of the sows. Of course, it is possible to create and apply separate curves according to parity, sow size, feed consumption, etc. On this farm, different curves are used for first farrowing sows, normal multiparous and high feed intake sows.

Example of first farrowing curve.

Example of curve of a normal multiparous sow.

Example of curve of a multiparous sow +10%.

The system was introduced in early summer, but the sows' appetite remains excellent, thanks to the dawn-to-dusk feeding schedule and the different ad libitum rations throughout the day, which perfectly meet the sows' needs. The average feed intake of the sows during lactation is 5.73 kg during 26.3 days of lactation on average.

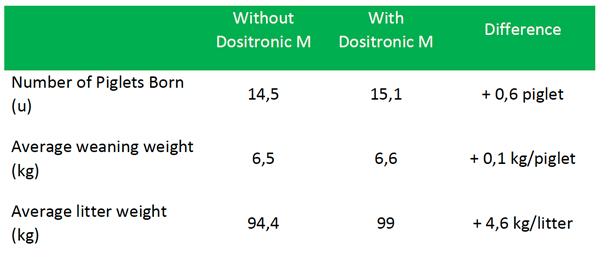

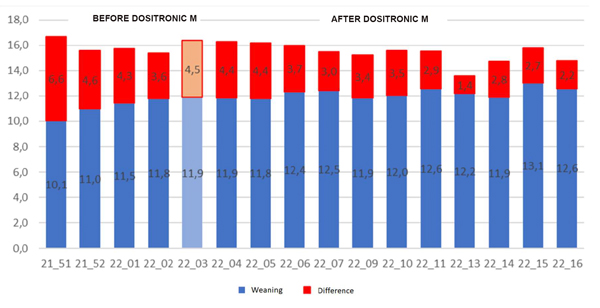

Improved feed intake had a positive effect on milk production, resulting in more balanced litters, fewer piglet deaths before weaning and higher weaning weights. The number of piglets born increased by 0.6 piglet, the average weaning weight also improved by 0.1 kg/piglet, resulting in a litter weight at weaning of almost +5 kg.

I emphasize that the Dositronic results were obtained in summer, and the control period (without Dositronic) is in the much more favorable winter-spring months.

Arguments are often heard to the contrary that frequent maternity feeding increases the mortality rate due to the sow lying on the floor. In practice, however, it is observed that more frequent feeding causes the sows to stand often and therefore eat and drink more, which clearly contributes to increased milk production, with improved weaning results.

What is very interesting is that, at the same time as milk production increased, the sows lost less backfat. On average, the rate of backfat loss at farrowing decreased from 4.72 mm to 3.12 mm.

Comparative of productive data without and with Dositronic M.

The economic cost of body condition loss can be clearly measured in terms of feed cost to replenish muscle mass and backfat. In this case, the feed requirement for condition regain after weaning is significantly reduced (5 kg/kg specific!).

In addition, further improvements in reproductive biology are expected in the next cycle due to less backfat loss and the reduced condition loss will reduce adverse metabolic stress, thus increasing the life span of the sows.

Last but not least, the great advantage of the electronic sow feeding system is the massive data collection, the even better knowledge of the sows' feed consumption habits, the evaluation of longer periods and the discovery of new correlations.

Conclusion

On the vast majority of pig farms, the number of appropriately qualified personnel is already insufficient, which clearly pushes investment towards automation. And with rising feed prices, feed wastage is no longer acceptable and further steps must be taken to improve efficiency.

The relatively high initial cost of automatic feeders for sows may be a deterrent to some, but I would suggest that we should consider the economic benefits gained in terms of dramatically reduced feed wastage, increased piglet numbers and weaning weights, and improved reproductive biology. Let's do the math and find out what it's worth.