Blog

Blog

What are the advantages of working with nests in transition?

14th April 2020 - Studies

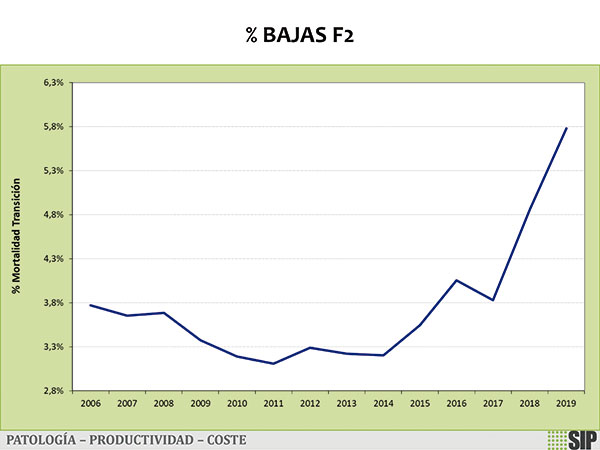

The progressive reduction in the use of antibiotics in pig farming has brought to light certain aspects that went unnoticed previously, such as inadequate facilities to ensure the thermal/environmental comfort of piglets. This deficit has highlighted a trend that pig farmers have seen in recent years: the worrying increase in the number of piglet weaning losses (Figure 1).

Figure 1

Mortality trend during weaning in recent years. Source: SIP Consultors (January 2020).

The ideal temperature for recently weaned piglets is 28/30 degrees, and it decreases proportionally during growth. In winter, obtaining this temperature for the total cubic meters of weaning rooms is, in many cases, unsustainable, so some farmers choose to lower the temperature to minimize costs (not to mention the fact that there are facilities where it is almost impossible from a technical point of view to achieve these temperatures). If we add to this the fact that the piglets are exposed, without any kind of shelter, to draughts with air temperatures far below the desirable, we have the right circumstances for all sorts of diseases to appear, and their capacity to grow reduced.

What can we do to improve this problem?

The inclusion of a nest in the weaning pens reduces these shortcomings because it allows us to create a thermal comfort space, free from draughts and with the ideal temperature for the piglets to grow satisfactorily, which is the same as achieving a suitable means of preserving their health and a substantial saving in heating costs.

Two climates instead of one

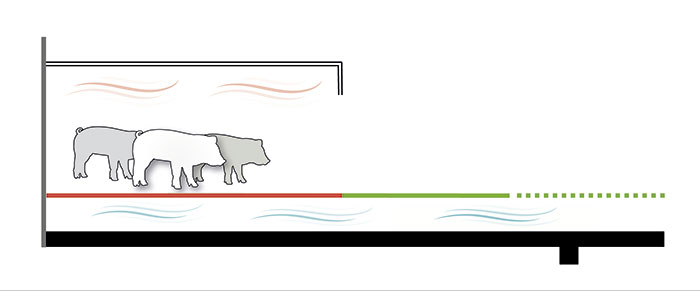

With two environments (one in the room and one inside the nest) not only does one save on the amount of energy needed to achieve the ideal temperature (in this case, less, because it is not necessary to raise it so much neither in the room nor the nest) but also the size of the heating equipment with hydraulic systems is affected. In a well-conditioned nest, the initial temperature to achieve the necessary 28/30 degrees should only be 22/24, because the other six are gained by the covering effect of the nest, which prevents temperature dissipation (Figure 2).

Figure 2

6ºC gain with the nest. The cover should not exceed 1.6m in length.

However, not everything is adequate to raise the temperature inside the nest. We recommend that the nest does not exceed 1.6 metres in length and that the fixed section of the wing does not exceed 12 centimetres, because in this way we guarantee the correct air renewal inside the nest.

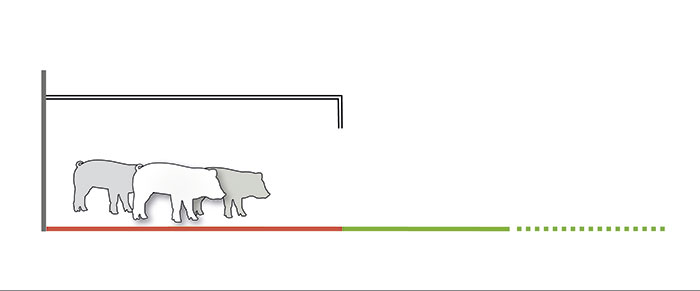

It is also important to note that draughts from the slurry pit should not affect the comfort zone in the nest. This requires a large area between the nest and the pit, which prevents the airflow from directly impacting on the resting area. It is advisable to size the slurry pit well and calculate its capacity well to avoid over-dimensioning it more than necessary (Figure 3).

Figure 3

A solid area between the pit and the nest is recommended to avoid draughts. Draughts from the slurry pit should be prevented from affecting the comfort zone.

For the new pen design, it is crucial to consider that the capacity of the nest will be the one that dictates the number of piglets per pen. To calculate this, the weight of the piglets at weaning and their growth during their stay in the room until their later transfer must be taken into account.